Industry Insights

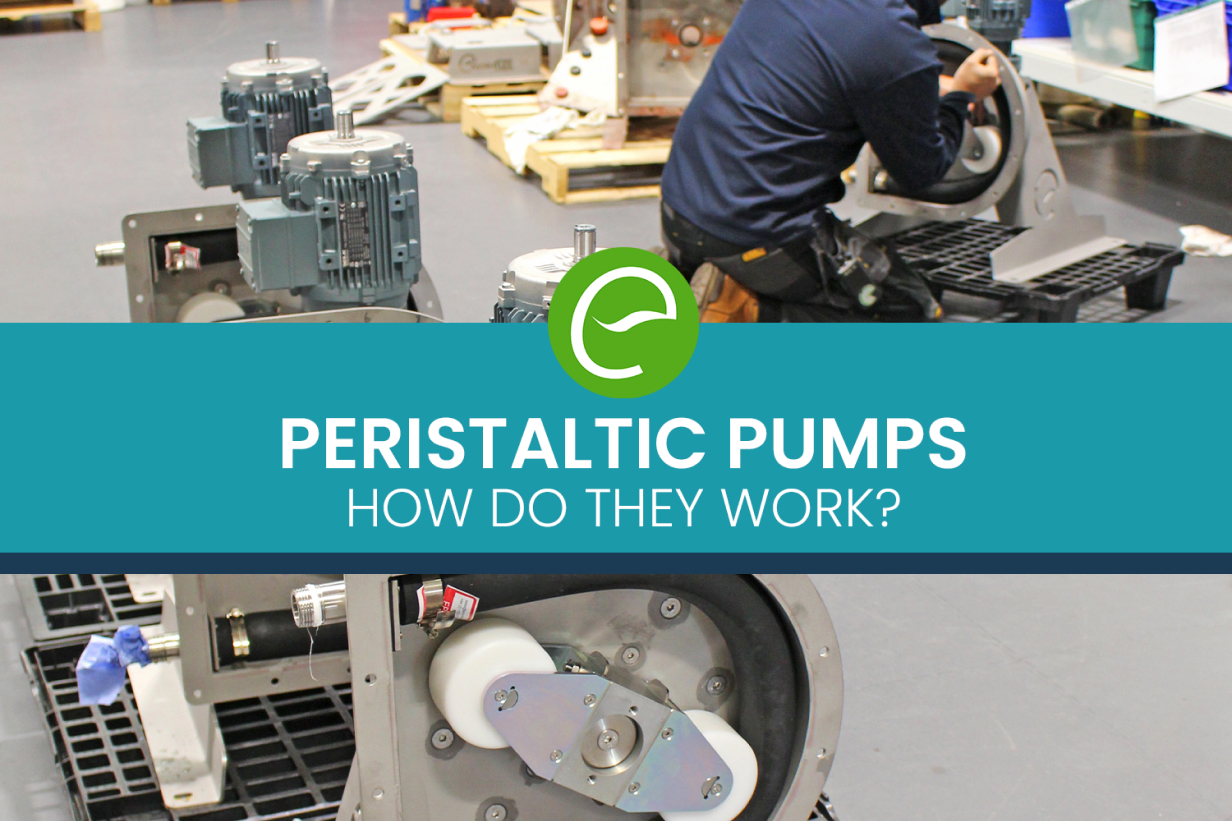

How Does a Peristaltic Pump Work?

Published on

15 August 2025

A peristaltic pump is a positive displacement pump that traps a specific volume of fluid and then moves it onward. Typically, a standard peristaltic pump features two rotating rollers or shoes housed within the pump body, along with a flexible rubber hose. As these rollers or shoes turn, they compress the hose, initially generating a vacuum that pulls fluid into the hose and subsequently propelling it out with their continued rotation. This pumping principle is called peristalsis, similar to the way our digestive tract works.

What are the advantages of a peristaltic pump?

Peristaltic pumps offer a wide range of advantages, making them a go-to solution for challenging pumping applications across industries like food, chemical, and wastewater treatment. Their simple yet highly effective operation is based on the compression and release of a flexible hose, which fully contains the fluid being pumped. This design gives peristaltic pumps a unique edge over many traditional pump types.

Clean, Contamination-Free Pumping

Because the fluid is completely enclosed within the hose, there is no contact between the pumped product and any moving parts, pump internals, or seals. This ensures absolute hygiene and eliminates the risk of cross-contamination. They are ideal for sensitive applications such as food production, pharmaceuticals, and chemical processing. Since the hose forms a sealed path, there’s also no risk of backflow when the pump stops, removing the need for check valves or additional sealing components.

Easy Maintenance with Minimal Wear Parts

One of the biggest maintenance benefits of a peristaltic pump is its simplicity. The hose or tube is the only component that wears over time, making servicing straightforward and low-cost. There are no mechanical seals, glands, or valves to replace or maintain, meaning downtime is kept to a minimum. Replacing the hose is quick and doesn’t require disassembling the entire pump.

Gentle and Versatile Pumping Action

Peristaltic pumps can handle a wide variety of fluids and materials with ease. Their gentle, low-shear pumping action makes them ideal for shear-sensitive products, while their robust design allows them to move highly viscous or dense fluids, abrasive slurries, and even solids. This includes hard particles, soft solids, suspended matter, and stringy materials, without jamming or clogging.

These pumps are also chemically resistant, able to handle corrosive or aggressive fluids without degradation of internal components. They are self-priming, capable of dry running without damage, and deliver excellent suction lift, even from significant depths. Their bi-directional operation means they can run in reverse, providing flexibility for filling, emptying, or system purging. Plus, they can operate at extremely low speeds, making them ideal for precision dosing and metering tasks.

How Are Enviroflex’s Peristaltic Pumps Different to Competitors?

While peristaltic pumps already offer a wide range of advantages, Enviroflex’s L Series takes performance, flexibility, and value a step further.

Our pumps are built with long-term efficiency in mind – delivering a low lifetime cost without compromising on quality. Whether you’re looking for consistent dosing, gentle handling of challenging fluids, or minimal maintenance, the L Series is engineered to deliver reliable performance in demanding environments.

One of the key differences lies in our broad size range, with models available from 15mm up to 150mm internal diameter, capable of handling flow rates up to 2,500 litres per minute (550 gallons/minute). This allows us to support everything from small-scale dosing to large-volume fluid transfer.

Our pumps are also custom-built to suit your process, each pump is made to order, giving you full control over the materials and configuration. Choose between mild steel, 304 stainless steel, or 316 stainless steel construction depending on your application needs. We also offer a range of connection types to suit different systems, including BSP, PN10, ANSI 125lb, and Tri-Clamp fittings for hygienic environments. Both metallic and non-metallic connection materials are available, and connection positions can be adjusted to fit your space and layout requirements.

A major advantage of choosing Enviroflex is our in-house hose manufacturing. We don’t rely on third-party suppliers, which means you benefit from consistently high-quality replacement hoses, shorter lead times, and full confidence in the compatibility and durability of your spares.

With exceptional build flexibility, quality components, and a commitment to keeping lifetime costs low, Enviroflex peristaltic pumps stand out as a smart, dependable choice for a wide range of industries.

What Industries or Applications Are Peristaltic Hose Pumps Suitable For?

Peristaltic pumps are widely used in industries where other pump types struggle. Thanks to their ability to handle viscous, abrasive, or chemically aggressive fluids—often with solids. They are known as reliable problem-solvers.

The hose material can be customised for chemical compatibility, making them ideal for sectors like chemical processing, nuclear, mining, wastewater, marine, food and beverage, brewing, paper, brickworks, automotive, and more.

Enviroflex pumps are already in use for applications such as:

Breweries – Transferring beer, yeast, and hop waste.

Bakeries – Pumping delicate, aerated batters.

Brick and tile manufacturing – Moving heavy, abrasive slurries.

Mining and aggregates – Dosing chemicals and pumping solid-laden slurries.

Chemical and CIP systems – Handling corrosive fluids like caustic soda.

Wastewater plants – Transferring raw and primary sludge.

Wherever difficult fluids are involved, peristaltic pumps offer a tough, low-maintenance solution.

What is the lifespan of a Peristaltic Pump?

The lifespan of a peristaltic pump can vary significantly depending on the application, operating conditions, and environment. However, one of the biggest advantages of this pump type is its serviceability; especially when it comes to wear parts.

The hose is the primary wear component, and it’s designed to be easily replaced once it reaches the end of its service life. How long a hose lasts depends on factors such as pressure, temperature, fluid type, and frequency of use.

You can read more about peristaltic hoses in our blog, Understanding Peristaltic Hoses.

Beyond the hose, internal components of the pump may require attention over time, but it’s not uncommon for us to service pumps that have been in operation for 10 years or more.

Motors and gearboxes can also experience wear, particularly in high-pressure or high-speed applications. Environmental conditions like heat, dust, and moisture can also play a role. Fortunately, Enviroflex has in-house expertise in motor and gearbox servicing, allowing us to assess and repair these components where it’s cost-effective to do so.

With regular maintenance and proper application, a peristaltic pump can deliver many years of reliable performance.

Browse Enviroflex’s Range of Peristaltic Pumps here.