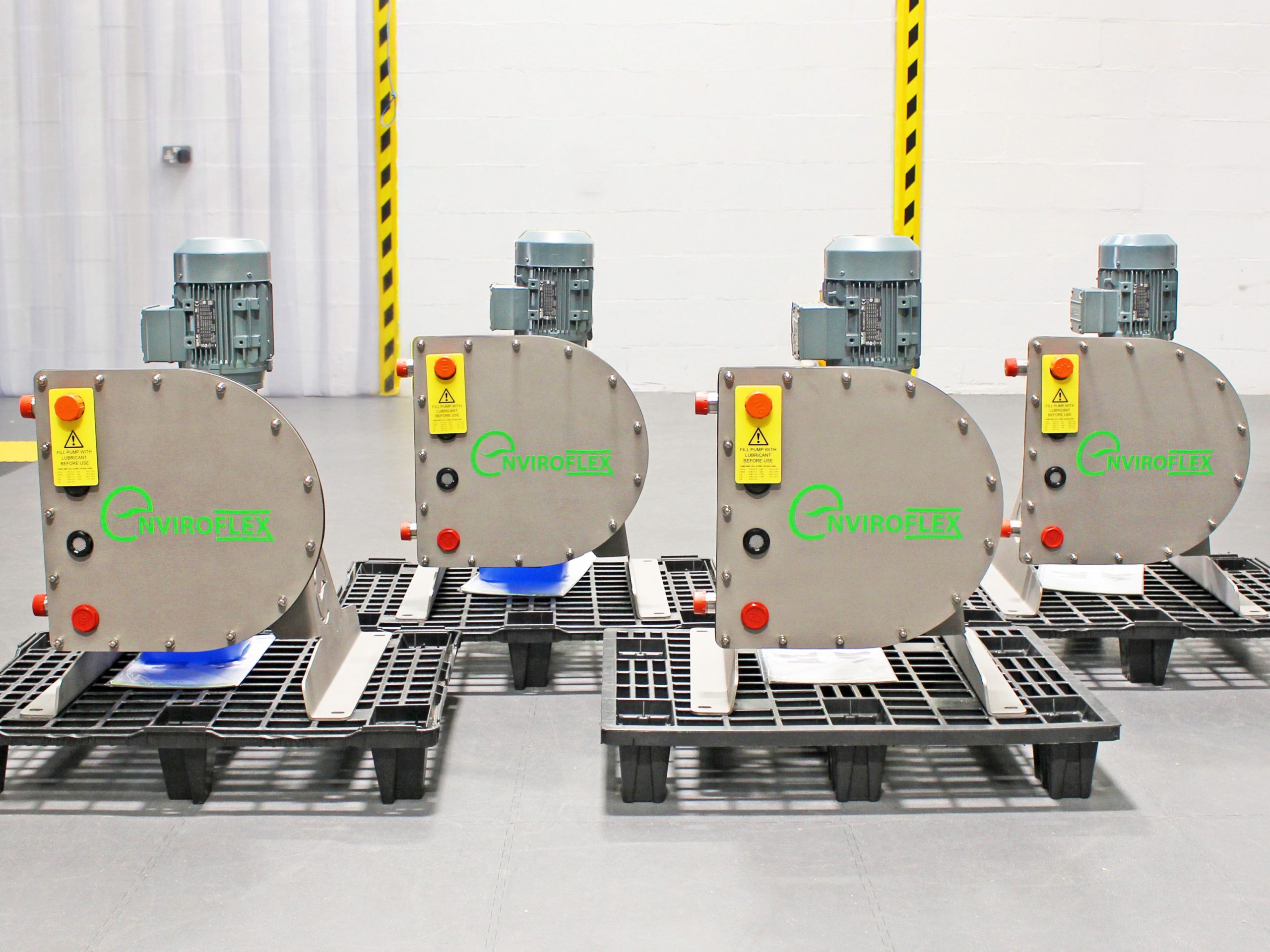

Peristaltic Pumps

At Enviroflex, our peristaltic pumps are engineered with one goal in mind: to maximise hose life. Built right here in the UK, our pumps focus on quality and precision, ensuring the hose—the heart of the pump—outlasts the competition. Unlike mass-produced, moulded cast iron pumps, we craft our pumps with flexibility in mind, optimising build quality and materials to deliver better performance across demanding conditions like speed, pressure, heat, and abrasion. Our hose pumps are fully customisable and made to order, ensuring suitability for almost all applications.

Filter by:

Key Features of Enviroflex Hose Pumps

Our pumps combine superior design with premium materials to extend hose life and maximise efficiency in your operations.

Extended Hose Life

Enviroflex peristaltic pumps are built to maximise hose life. Get the best performance from your hoses and avoid costly downtime.

Positive Displacement

Dry running and self-priming, these pumps operate in both directions — perfect for CIP processes. They run at low speeds, and when stationary, no fluid passes through.

Gentle but Robust

Our peristaltic pumps handle shear-sensitive fluids like batter and even whole fish. They’re also tough enough for abrasive, stringy, viscous, or corrosive products — as well as hard or soft solids.

Questions and Answers

Some questions are answered here but if you have more specific questions please don’t hesitate to get in touch

Peristaltic pumps are a fantastic solution for tough pumping tasks, especially with abrasive, corrosive, or viscous fluids. With no valves, seals, or glands, maintenance is simple — it’s just the hose you’ll need to replace. The gentle pumping action makes them ideal for delicate and shear-sensitive products, and because only the inside of the hose touches the fluid, cleaning and sterilisation are straightforward. Key advantages:

- • Fluid stays fully contained within the hose — no gaskets, seals, or rotors to clog or wear out.

- • Lower maintenance and spare parts costs.

- • Gentle handling of sensitive materials, like batter, yogurt with fruit pieces, or even whole fish.

- • Handles fluids containing gas.

- • Self-priming and can run dry without damage.

- • Suction capability up to 9 metres.

- • No slip, with excellent dosing accuracy.

- • Reversible flow for extra flexibility.

Absolutely. We’ll look at your pipework sizing, lengths, and operating conditions to recommend the best pump configuration for your system. We’ll also advise on any tweaks to your setup to get the best results.

They can, especially if the system isn’t configured correctly. But don’t worry — we can advise you on minimising this, and we also offer Pulsation Dampeners to smooth out the flow where needed.

Yes, they are. We can build your pump to handle corrosive fluids and withstand harsh environments. Take a look at our Hoses section for details on materials and compatibility. Or just get in touch — we’re happy to discuss your specific application.

They can be! Our pumps can be set up as fixed speed, dual speed, or fully variable speed, and they can run in both directions for maximum flexibility.

Yes. We can build pumps in stainless steel and use hoses specifically designed for food use. Plus, the lubricant we use is approved for hygienic applications, so you can pump food-grade products with confidence.

Upgrade To A Peristaltic Pump, Built For Your Process

Speak to one of our experts today and discover a pump tailored to your exact application.