Industry Insights

Understanding Peristaltic Hoses

Published on

1 October 2025

Peristaltic hoses are the most important component of peristaltic pumps. As the primary element, these hoses are the only component to make direct contact with the liquids being pumped. As a result, they experience the most wear and tear. Therefore, it is essential to utilise high-quality peristaltic hoses that are compatible with the specific fluids involved. This helps to ensure efficient and reliable pump operation while minimising maintenance and downtime. Peristaltic pumps operate by compressing and releasing a flexible hose, mimicking natural peristalsis, to create a consistent flow of fluid. For a deeper dive into the mechanics and benefits of peristaltic pumps, visit our detailed peristaltic pump blog. Understanding the role and characteristics of peristaltic hoses is vital for optimising the performance of these versatile pumps.

The Construction of a Peristaltic Hose

The construction of peristaltic hoses is crucial for ensuring optimal performance. These hoses are composed of multiple layers of rubber, each designed for a specific purpose. The inner liner is directly responsible for the hose’s interaction with the fluid being pumped, making its compatibility with the fluid essential. For more information about the various materials available for Enviroflex Hoses and their compatibility with different liquids, see our comprehensive hose material blog. Surrounding the inner liner, peristaltic hoses include several reinforcement layers, typically between two and six, usually crafted from natural rubber. These reinforcement layers provide structural stability and durability, ensuring the hose’s endurance in demanding applications. The layered construction is key to maintaining the hose’s integrity and function over time.

What Affects a Hose’s Life?

The lifespan of a peristaltic hose is significantly influenced by its application and the characteristics of the fluid being pumped. Factors such as the fluid’s temperature, abrasiveness, and its chemical compatibility with the hose material play critical roles. Additionally, the pump’s configuration and usage patterns impact hose longevity. Key considerations include: pump speed, whether the pump operates continuously or intermittently, inlet and outlet pressure, pulsation effects, and pump type features like hose track radius. Notably, a shoe-type pump might wear out the hose more quickly than a roller-type pump. Proper hose lubrication, the ambient temperature, and the degree of hose occlusion are also crucial for extending hose service life.

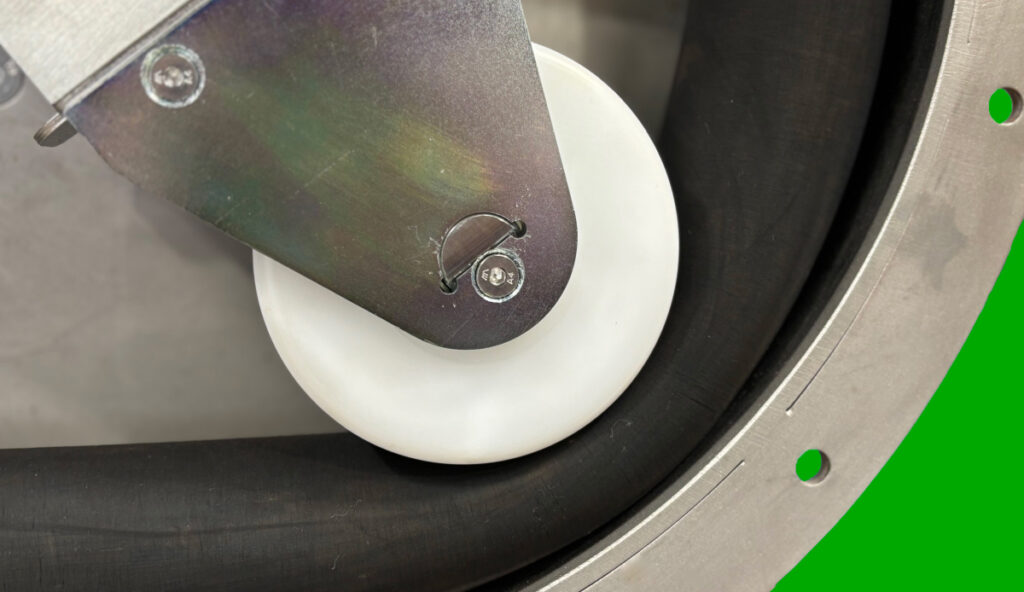

The Importance of Hose Occlusion

Proper hose occlusion setup is essential for maximising the efficiency of your hose and pump system. The hose needs to be adequately compressed by the roller or shoe to prevent fluid from leaking past these components, thus reducing internal wear caused by jetting. However, over-compression should be avoided as it can amplify the stress on the gearbox and raise the heat produced by the roller or shoe as it moves along the hose. This can also impact energy consumption and flow rate. Occlusion must be properly aligned with the pressure requirements of the application. Users should refer to the pump manual for detailed instructions.

Hose Lubrication

Hose lubricant plays a critical role in maximising hose life by reducing internal friction and efficiently dissipating heat. Enviroflex offers two standard lubricant formulations, each specifically engineered for either roller or shoe-type peristaltic pumps. These lubricants are optimised for performance, featuring strong adhesion to the hose surface, low freezing points, and excellent stability in cold environments. By contrast, inferior lubricants are often prone to thickening or becoming soapy at low temperatures—even above freezing—which can compromise pump efficiency and hose durability.

To support predictive maintenance, we recommend logging the hose installation date and total run time to failure. Monitoring changes in flow rate and power consumption can also serve as early indicators of hose wear or impending failure.

Browse our range of lubrication here.

Enviroflex Hoses

Enviroflex manufactures high-quality peristaltic hoses designed to be compatible with most major peristaltic pump brands. Our hoses deliver equivalent chemical resistance and performance to leading OEM products. We produce hoses with internal diameters ranging from 5 mm to 200 mm, and lengths from 350 mm up to over 5 metres, supplying customers worldwide—from Australia to Zambia.

Our in-house manufacturing facility is staffed by skilled technicians and engineers, allowing us to offer both standard and fully bespoke hose solutions tailored to your specific requirements. If your application requires a unique size, reinforcement level, or finish, we can manufacture a hose to suit.

To minimise downtime, we recommend keeping spare hoses on hand for immediate replacement, along with other essential consumables such as hose lubricant, spare rollers or shoes, and high-torque hose clips. Proactively replacing these components during scheduled maintenance can help avoid unexpected failures and maintain system reliability.

Browse our range of peristaltic hoses here, or find information about or bespoke solutions here.